I like post-apocalyptic themes. And Fallout games. There might be a special kind of pleasure when reading some post-apo SF novel and looking at your custom-made PipBoy derivative. Therefore I decided to build one! For you who don’t know how PipBoy 2000 from Fallout 1&2 looks like:

Since building real functioning PipBoy with genuine vintage components would be a monumental task, I focused on stationary device. In fact, I was particularly inspired by this contraption:

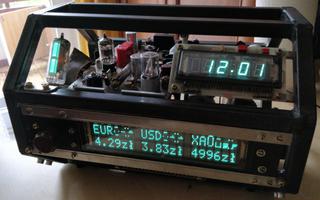

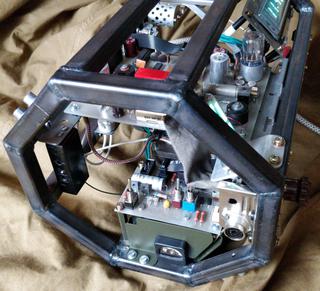

In-game, it is supposed to be a post-apocalyptic survival simulator proudly made for you by Vault-Tec. It has an open layout: the chassis is a steel skeleton which holds all internal components in place, they are clearly visible by the way. Gluing the ideas together, I came up with following requirements:

- Vintage, dirty industrial look&feel. Naked steel, visible cables and PCBs.

- Old school display. I considered CRT tube but since driving it is quite problematic, I decided to use alphanumeric vacuum fluorescent displays instead.

- The display has to provide following information information: date, time, current weather and also forecast, some RSS feeds and other stuff not yet devised.

- The device should be connected to the Internet to gather data. The connection may be done by some of the well-known Wi-Fi modules or single board PC.

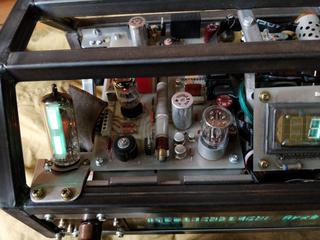

Early concept consisted of only one PCB - the one containing the dot-matrix display. After completing this module I decided to create more and mount them on unusually wielded steel chassis made of two octagons - therefore Octoglow was chosen as the name of the device. The project since then has grown seriously but so has the fun!

Currently, the device is made of following modules:

- Main display board, called

front-displayin the source code, contains 2x20 VFD dot-matrix display, its driver, power supply, and rotary encoder dial. - Supplemental board, designated

clock-display; four-digit VFD display, 433 MHz receiver, two relays to drive auxiliary loads. - Geiger counter board, containing highly unusual circuit of Geiger-Müller counter and driver of EM84 magic eye tube. Deliberately designed to use as many unusual components as possible. (

geiger) - Controller board with Orange Pi Zero single board computer as its heart, I²C level shifter, DAC to drive analog gauge meters and IDC connectors in order to connect together all modules by system bus. (

orangepi-holder)

There is still quite a lot of space within the chassis, I may add another board in the future. If you have any ideas for it, let me know!

Every PCB was designed in KiCAD, that includes custom footprints for vintage elements. All design files and source code is available on GitHub.

My explicit goal was to include many vintage components, each of them has its own backstory. After many years I still remember the way I came into possession of some of this stuff. When I do, I put notes in appropriate places in the description.

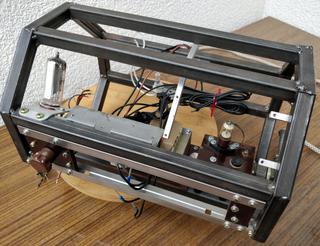

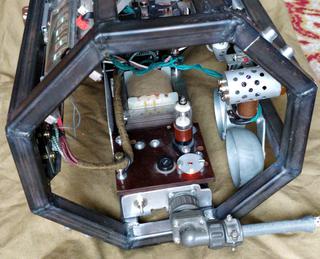

Power supply

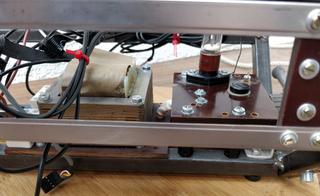

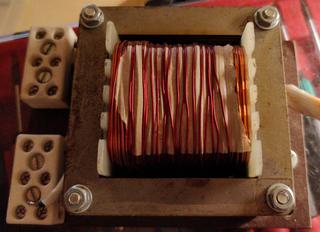

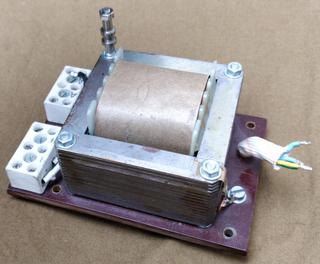

The device is powered by transformer, which provides two voltages: 24 V and center-tapped 5 V. The second winding was wound by me by hand in order to power the VFD filaments. The main board contains the power supply circuit, more about this in the article.

Transformer comes from an old medical device I have torn apart as a child.

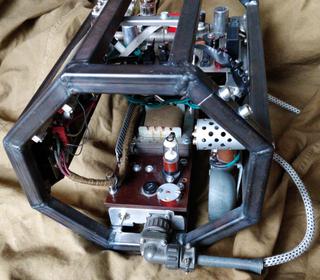

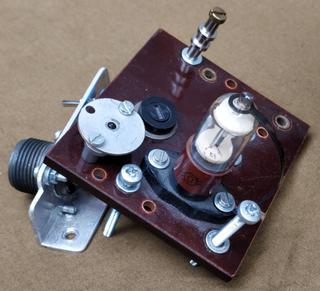

The device draws its power from 230 V 50 Hz mains. I used braided cord from an old iron. The mains side is protected by lighting arrester RB-5. It might be an overkill, but the glass envelope sure does look cool, doesn’t it? As you can see in the photos, military socket is used for power.

The transformer generates 24 V, which is routed to the front display board. I used braided wires for power distribution within the device. As I said previously, I had wound additional center-tapped 5 V winding for the VFD display filaments. I did it in the following manner. First I wound ten turns and measured the output voltage. Then I calculated the required number of turns for 5 V. It was about 30. It was quite tricky to wind them without disassembling the core but achievable indeed.

Some of the wiring within device is done with magnet wire insulated in double layer of cotton. The wire comes from an ancient generator from 1920s. This generator used to serve as an electricity source in the mill located in my father’s home village. He has obtained it in some murky circumstances. This way, I’m using hundred-year old wire in my plaything.

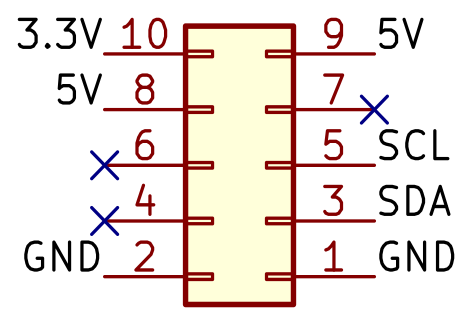

24 V AC goes to two circuits on the main display board - voltage doubler for providing supply for VFD anodes and step-down converter to generate system voltage 5 V DC. There is also 3.3 V stabilizer. 5 V and 3.3 V are available on the system bus. Whole device draws ~15 W with magic eye powered on and ~10 W with eye shut down.

System bus

All modules are connected by 10-pin IDC cable. It provides supply voltages: 5 V and 3.3 V and also I²C bus. The exact pinout was inherited from one of my previous unfinished projects - therefore three unused pins. The pinout itself:

Indoor weather sensor BME280

Encased in fancy cylindrical case made of RF coil shielding with holes drilled. The main purpose of the case is to shield the modern look of BME280 from the viewers eyes, so it does not disrupt the vintage feel of the device.

BME280 is an integrated temperature, humidity and pressure sensor. It is widely available as cheap Chinese module, which also has voltage stabilizer and I²C level shifter. However, these particular modules are low quality. In the end I decided to skip measuring humidity at all since it failed to bring me accurate readings.

The Chinese module I used sets the I²C address of the module to 0x76.

External I²C socket

The device has external 4-pole DIN circular connector with following pins:

- shield - GND

- 1 - SDA

- 2- SCL

- 3, 4 - no connection

During development I run the octoglowd software on the PC and controlled the device through USB to I²C converter. At first I simply connected to I²C line on VGA port. However after changing graphics card on my PC from ATI to nVidia VGA was no longer available, furthermore I²C on HDMI failed to function correctly. I tried other solutions but stayed with Digispark module flashed with i2c-tiny-usb firmware. In my experience this is the most convenient I²C to USB bridge. It is supported in Linux kernel directly so I use exactly the same software on the PC and on Orange Pi Zero.

Octagonal skeleton chassis

The skeleton is made of 15 mm rectangular pipes. In some of the photos you can see that wielding is not completed - the skeleton was barely wielded by me just to hold the shape. After the development process is finished, the remaining job was done by a professional.

Dimensions are as follows:

- width 30 cm

- overall height 21 cm

- octagon sides 8 cm, 9 cm

The skeleton is made of two parts joined by four M6 screws. You can disconnect them to access the interior.